A/S Norske Shell creating the first-ever fully integrated reservoir to market digital twin

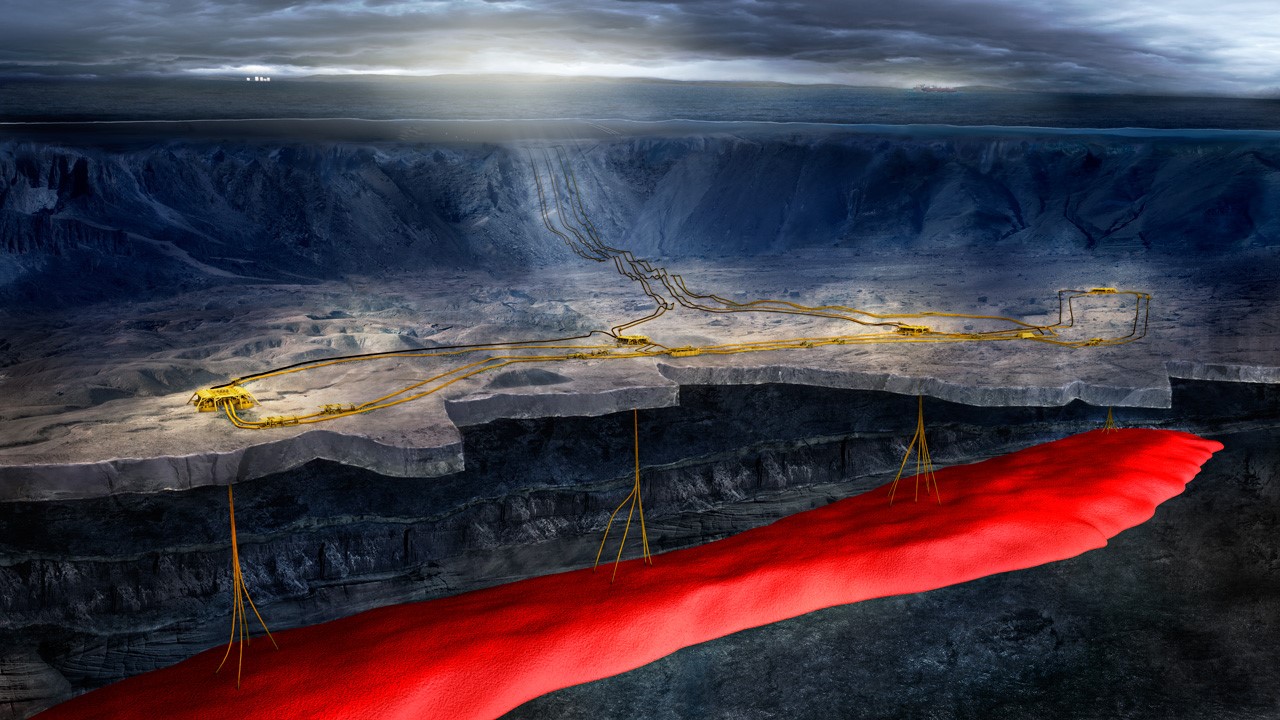

Oslo — Norske Shell is using Kongsberg Digital’s digital twin solution Kognitwin® Energy to create a virtual representation of their Ormen Lange deepwater gas field. Feeding into the onshore digital twin developed at Nyhamna gas processing facility, the two will be combined and becomes the first-ever fully integrated reservoir to market digital twin.

The twin solution from Kongsberg Digital will reimagine the ways of working at Shell and unlock new value in the subsea and subsurface arena. By focusing efforts on digital solutions that scale across assets and installations it is easy to expand and integrate Ormen Lange into the existing onshore dynamic digital twin developed at Nyhamna gas processing facility, resulting in the first ever fully integrated reservoir to market digital twin.

In October 2019, Norske Shell joined forces with Kongsberg Digital to operationalize an ‘asset of the future’ through a partnership development of the Nyhamna Dynamic Digital Twin, using Kongsberg Digital’s Kognitwin Energy solution. The twin was deployed and up and running by the end of the year and since January 2020 the Nyhamna Dynamic Digital Twin has been in operation and evolving continuously through monthly product releases, focusing on safe, effective and integrated work processes and optimization of production and energy use. With Nyhamna having paved the way, the decision was made to expand the collaboration with another digital twin of the related Ormen Lange deepwater gas field, which feeds gas to Nyhamna.

With Ormen Lange, we are very proud to have been awarded the contract for the development of a second digital twin for Norske Shell. This is a direct result of our successful collaboration around the Nyhamna dynamic digital twin. We would particularly like to highlight a strong core product, Kognitwin Energy, rapid deployments, and fast time to value as unique differentiators in this ongoing project. Now, we are eager to help Norske Shell realize the full potential of their assets through integration of these two digital twins, says Hege Skryseth, President of Kongsberg Digital and EVP KONGSBERG.

The first version of the Ormen Lange digital twin comprises primarily data integrations and visualization of subsea 3D models including production and MEG pipelines, well surface locations and well-bore paths, seabed bathymetry data detailed around the production templates, built documentation and drawings, real time data from DCS and PI and much more.

For disciplines and teams across the initial Ormen Lange user base – like Subsea Maintenance, Wells, Flow Assurance, Production Technology, Reservoir Engineering, Process Engineering and Operations – the twin provides unified data for everyone to access across the same work surface. This is the starting point of a long journey where Kongsberg Digital and Norske Shell will continue to develop valuable features and target specific use cases to enable user groups, disciplines and teams with new ways of working.

Digital twins are technology for people. The partnership model, combining Kongsberg Digital’s digital capabilities with our own employee’s expertise in the operations and maintenance domain, has been very effective in delivering use cases that let our teams to collaborate better and become more effective. This in turn enable us to save costs and optimize production whilst improving safety and environmental impact, says Rolf Einar Sæter, Digitalisation Manager in Norske Shell.

The first version of the Ormen Lange digital twin was released to users in Norske Shell last month.